Cable Manufacturers

UK Manufactured Specialist High Performance Cables

& Wires for Extreme Environments

Industries

We provide tailored cable solutions

designed to meet your unique needs.

Let’s guide you to the perfect

cable to suit your needs…

Specialist High Performance Cable Manufacturing since 1984

Heatsense Cables is one of the UK’s leading cable manufacturers of specialist high performance cables that operate in extreme environments from -273°C (-459°F) to +1250°C (+2282°F). Our range includes cables that are resistant to flame, oils & chemicals, operate in ultra-high-vacuum, low outgassing, cryogenic and high radiation environments.

Our cable manufacturing processes include fluoropolymer extrusion, high-performance taping & cable wrapping, cover sintering, colouring, etching and application of specialist coatings.

Insulation materials include, PFA, FEP, PTFE, ETFE, XLETFE, PEEK, EFGLAS, SILICONE, PE, PU, PVC, Taped & Sintered PTFE, Mica, Polyimide & Aramid Yarns and PTFE impregnated yarns.

Cable braiding materials include, glass, quartz & ceramic fibres, specialist aramid yarns and various metals.

Our highly experienced team have industry leading technical specialist cable design knowledge and bespoke cables with advanced design & development service. As we design, develop and manufacture cables in house, we have the internal skills to undertake development work on new cable designs and materials and work on projects in aerospace, nuclear and the R&D sectors amongst others.

Accreditations and Certifications

- AS/EN 9100:2018 (Rev D)

- ISO9001:2015

- ISO14001:2015

- Rolls-Royce SABRe 3

- F4N (Fit for Nuclear Status) awarded by the Nuclear Advanced Manufacturing Research Centre (NAMRC)

- JOSCAR Registered

- ADS (Aerospace, Defence & Space) Certified

- Cyber Security Certified

- Member of NWAA (North West Aerospace Alliance)

- Made in Britain

Advanced Cable Design for Extreme Conditions Across Multiple Industries

Our industry leading team of cable engineers use a broad range of insulation materials, which allow us to manufacture cables that are resistant to heat, cold, fluid, particle ingress and radiation. Nuclear, Automotive Aerospace, Oil & Gas and Medical industries, to name but a few.

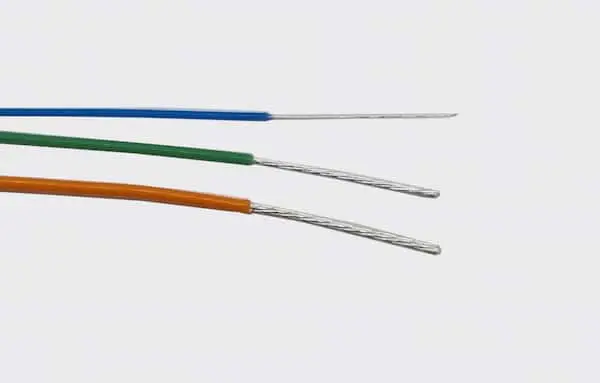

Expertise in Specialised Cabling with Advanced Insulation Materials

Our insulation materials include PFA, FEP, PTFE, ETFE, PEEK, EFGLAS, Kevlar, Kapton, Mica, Quartz, Glass & Ceramic Fibre, Cross-Linked & Halogen Free Materials.

Our team have the versatility, knowledge and expertise to manufacture cables for highly specialised uses. Contact us today to discuss your requirements.

Personalised solutions for every industry

Sensor Wires

Heat Resistant Cables

Thermocouple Cables

Equipment Wire

Bespoke Cables

RTD Cables

Cryogenic Cables

Glass Fibre Cables

INTEMP Cables

Kapton Cables

Sub-miniature Hook up Wires

UL Hook-up Wires

See how we solve problems, with precision

Quotes from Our Clients

Cable Manufacturers FAQs

What cable manufacturing processes are used to protect electrical and signal cables used in extreme heat and radioactive environments?

If you are looking to protect electrical and signal cables used in extreme heat and radioactive environments , you need plenty of layers which have specific protection capabilities. Heatsense apply the following cable manufacturing processes including braiding, extruding, and coating with heat and/or radiation-resistant materials as well as various liquid ingress protection coatings. The specific process used depends on the requirements of the application.

What materials are used for extrusion coatings on cables manufactured for extreme heat and radioactive environment

Materials commonly used for extruding coatings on cables for extreme heat and radioactive environments include polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), and fluorinated ethylene propylene (FEP). These materials have excellent temperature and chemical resistance properties.

In the manufacturing process, how are cables tested for resistance to extreme heat and radiation?

Cable manufacturers like Heatsense test for resistance to extreme heat and radiation using a variety of methods, including thermal cycling, radiation exposure (carried out by a specialist partner), and mechanical testing. Testing is typically done in accordance with industry standards to ensure accurate and reliable results.

What is the typical lifespan of cables manufactured for use in extreme heat and radioactive environments?

The lifespan of cables used in extreme heat and radioactive environments depends on a number of factors, including the materials used, the level of exposure to heat and radiation, and the application requirements. Cable manufacturers can provide guidance on the expected lifespan of cables for specific applications.

Can cables be customized to meet specific application requirements for extreme environments?

All Heatsense cables can be manufactured to order, therefore can be customized, combined into multi-strand configurations and braided into a single large cable to meet any specific application requirements for extreme environments. We are constantly innovating with our cables and can work with you to develop a customized solution that meets your unique needs.

How are cables manufactured to protect them against corrosion in extreme environments?

Heatsense cables are manufactured to be protected against corrosion in extreme environments by using materials that are resistant to corrosion, such as stainless steel and a range of plastics. Additionally, a range of different coatings can be applied to further protect the cables from corrosion. Heatsense cables design team will support you in choosing the right materials and coatings for your specific application.