Company background

Heatsense Cables was established in 1984 and operates from a single manufacturing facility in Rochdale, Greater Manchester, UK.

Since the early 1980’s it has grown to become one of the leading specialist high-performance cable manufacturers in the UK and Europe. The company offers a bespoke advanced technical design and manufacturing service and undertakes development work on new cable designs and materials.

The range covers cables that are resistant to flame, oils & chemicals and which operate in ultra-high vacuum, cryogenic and high radiation environments. The company manufactures cables that are capable of operating in extreme environments, from -273°C (-459°F) to +1250°C (+2282°F).

Heatsense is an approved supplier to numerous international companies in aerospace, space, nuclear, oil & gas, R&D and general industry.

Accreditations and Certifications

AS/EN 9100:2018 (Rev D)

- ISO9001:2015

- ISO14001:2015

- Rolls-Royce SABRe 3

- F4N (Fit for Nuclear Status) awarded by the Nuclear Advanced Manufacturing Research Centre (NAMRC)

- JOSCAR Registered

- ADS (Aerospace, Defence & Space) Certified

- Cyber Security Certified

- Member of NWAA (North West Aerospace Alliance)

- Made in Britain

Our team

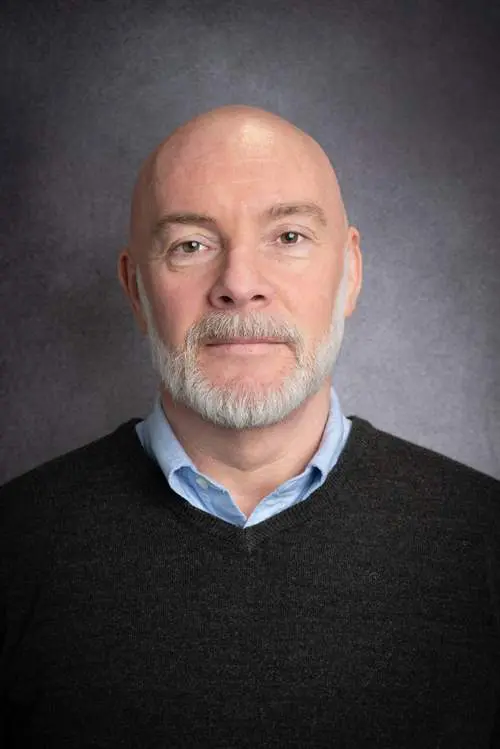

Matt Ashton

Operations Director

Conor McCondichie

Commercial Manager

Craig Hulse

Production Manager

Jane Harris-Cookney

QMS Manager

Pete Howarth

Continuous Improvement Manager

Kerry Miller

Senior Customer Service Advisor

Our purpose

Producing high-performance cables that meet customer needs.

Achieving operational excellence through innovation and efficiency.

Conducting business safely, sustainably, and responsibly.

Upholding robust management systems and ethical standards.

Ensuring excellence in Health, Safety, Security, and Environmental practices.

Quality assured

Accreditations and Certifications

- AS/EN 9100:2018 (Rev D)

- ISO9001:2015

- ISO14001:2015

- Rolls-Royce SABRe 3

- F4N (Fit for Nuclear Status) awarded by the Nuclear Advanced Manufacturing Research Centre (NAMRC)

- JOSCAR Registered

- ADS (Aerospace, Defence & Space) Certified

- Cyber Security Certified

- Member of NWAA (North West Aerospace Alliance)

- Made in Britain

Commitment to quality and customer satisfaction

At Heatsense, we prioritise customer satisfaction by delivering products that meet international standards and specific requirements. We focus on high quality, excellent delivery performance, and competitive pricing to exceed customer expectations.

Maintaining Global Quality Standards

Heatsense upholds global quality standards set by ISO through employee training, internal audits, controlled documents, and BSI Assurance Limited approvals.

Our Offer

The company also offers a bespoke technical design & manufacturing service. Whether it’s a large project or simply a unique requirement, you can talk to us about our bespoke cable design service. Markets include automotive, aerospace, nuclear, medical, R&D, Oil & Gas and general industry.

We are highly customer focused and offer a bespoke advanced technical design and manufacturing service, coupled with rapid response times, short lead times, low MOQ’s and competitive pricing.

You can speak to one of our dedicated advisors right now, they’ll speak with you to understand your needs and establish the best solution at the right price.