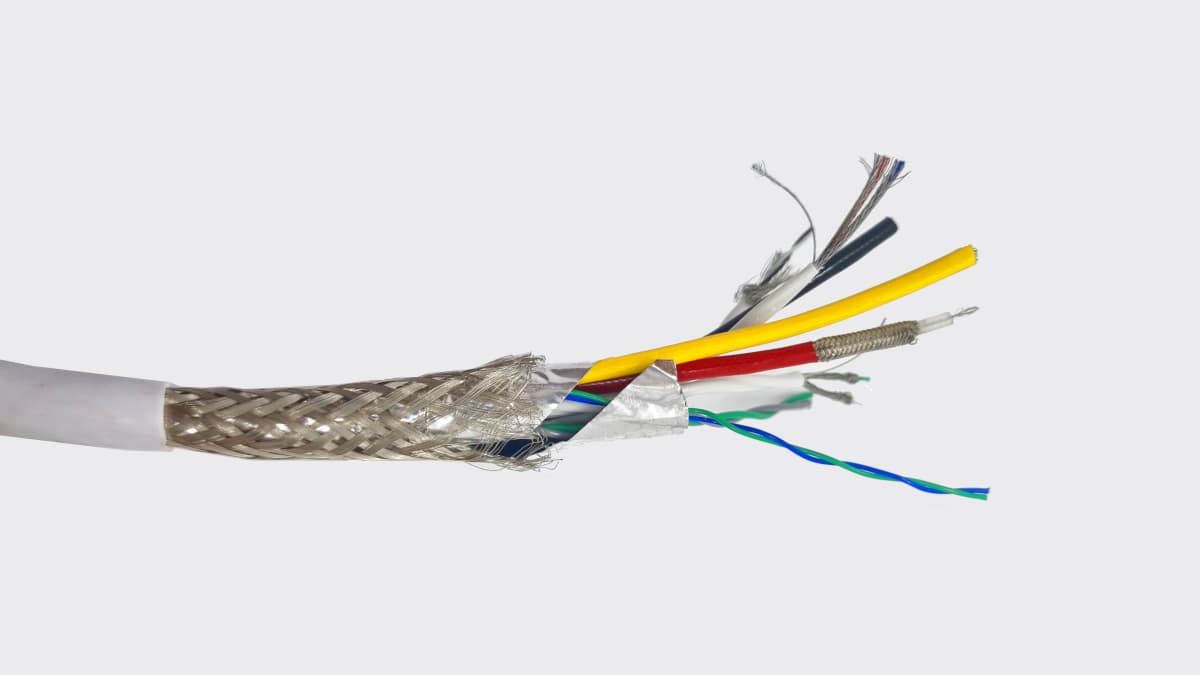

Design

Our advanced cable solutions are designed to meet the rigorous standards of the most extreme industries, ensuring seamless performance in demanding environments.

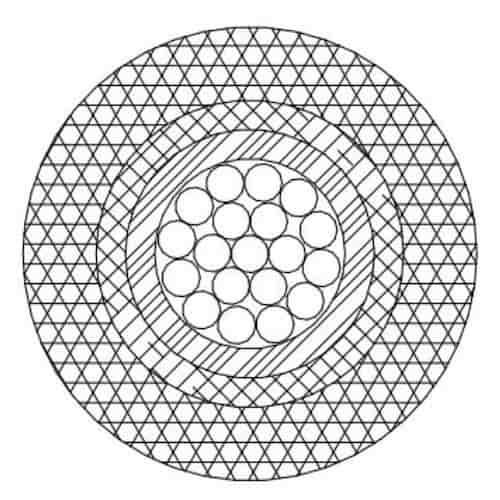

Braiding

Our cable braiding process adds critical protection to our cables using a range of materials to suit the requirements of the environments in which they are be installed.

Taping

Taped cables are designed to provide exceptional thermal stability, chemical resistance, electrical insulation and radiation properties, making them ideal for use in the most demanding applications.

Sintering

Using temperature controlled ovens, Heatsense heat taped material to just below melting point, allowing it to form a cohesive uniform layer that enhances the durability and resistance to harsh environmental conditions.

Extrusion

Using a purpose built extrusion line, Heatsense coat cables with PTFE, known for excellent temperature resistance, chemical inertness, and electrical insulation, is an ideal material for demanding applications.

Twisting & Laying up

The cable twisting process is designed to ensure the cable’s mechanical stability, flexibility, and overall performance, particularly in demanding applications where reliability is paramount.

Heatsense produces bespoke cables to meet environmental requirements and specifications. Our cable design engineers and manufacturing team are able to manufacture cables that provide consistent stability in the most extreme environments.

Our tailor-made, cost-effective cable solutions meet all international standards. The company also manufactures a wide range of more standard high-performance cables.

As such, our cable design and manufacturing service covers all industries including aerospace, nuclear, oil & gas, medical, automotive and industrial.

Please complete the form below to give our bespoke cable design team an idea of what you are looking for including any specific international standards if necessary?