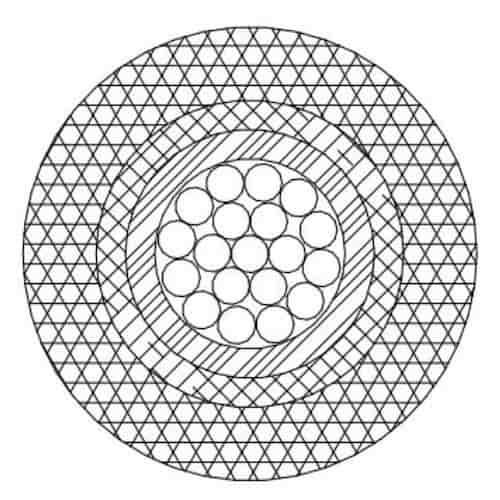

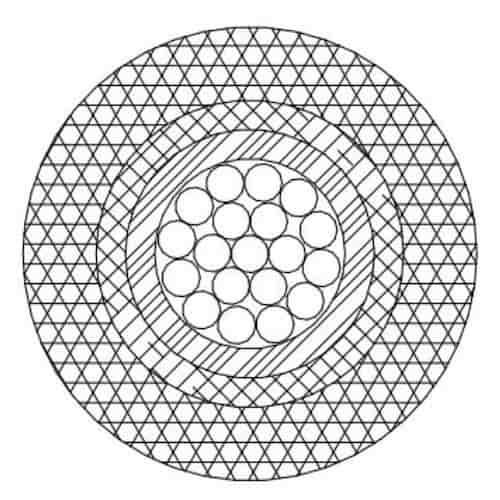

Heatsense offers cable design services for a wide range of industries and leading-edge technology companies. With our extensive expertise and experience, we have successfully designed cables that have been utilised in some of the most demanding and high-profile projects worldwide, including CERN’s Large Hadron Collider, ITER’s Tokamak Reactor, Rolls-Royce aerospace test rigs and several companies developing nuclear fusion technologies.

Our cable design service encompasses a thorough understanding of your specific requirements and the ability to create innovative solutions that excel in extreme conditions. Depending on their design, our cables are capable of operating in extreme environments ranging from -273°C (-459°F) to +1250°C (+2282°F) and with additional protection from radiation, electrical interference, external pressure based on very stringent tolerance requirements.

What expertise does Heatsense Cables offer in cable design for extreme environments?

Heatsense Cables specializes in designing cables that operate in extreme environments. Our experienced team possesses a deep understanding of the unique challenges posed by extreme conditions, such as high and low temperatures, exposure to chemicals, radiation, ultra-high vacuum, low outgassing environments and mechanically demanding stresses.

Our expertise lies in developing cables that offer exceptional performance, reliability and durability, ensuring they meet or exceed the requirements of applications in diverse industries. From particle accelerators to nuclear reactors and aerospace testing rigs, our cable designs have proven themselves in some of the most challenging environments on the planet and in space.

What factors should be considered when ordering cable design services for extreme environments?

When enquiring about cable design services for extreme environments, several factors need to be considered. The operating temperature range is of utmost importance, as it determines the conductor and insulation materials that can withstand the required temperatures.

Additionally, the cable’s resistance to chemicals, radiation, low vacuum environments and mechanical stresses need to be considered.

Other considerations include the required electrical properties, such as conductivity and shielding, as well as the cable’s flexibility, size, and weight. By providing us with comprehensive information about your application’s specific requirements, we can tailor our cable design services to deliver a solution that precisely meets your needs.

What is the operating temperature range of the cables designed by Heatsense Cables?

The operating temperature range of our cables can vary based on the specific requirements of your application. We design cables capable of withstanding temperatures ranging from cryogenic conditions from -273°C (-459°F) to extremely high temperatures exceeding +1250°C (+2282°F).

Can the cables withstand exposure to chemicals and corrosive substances?

Yes, our cable designs are developed to withstand exposure to a wide range of chemicals and corrosive substances. We select materials and insulation systems that exhibit excellent resistance to chemicals and ensure long-term durability and reliability.

Do you provide custom cable designs for specific applications?

Absolutely! Our cable design services are flexible enough to ensure a customised solution for your specific needs. We work closely with you to understand your needs and develop tailored solutions that address the challenges posed by extreme environments.

Are your cable designs suitable for high-voltage or high-current applications?

Yes, we have extensive experience in designing cables for high-voltage and high-current applications. Our designs incorporate appropriate insulation systems and conductor materials to ensure reliable performance under demanding electrical conditions.

Can you provide certification and documentation for regulatory compliance?

Yes, we understand the importance of regulatory compliance. We can provide the necessary certifications, documentation and test reports to ensure our cable designs meet the relevant industry standards and regulations.

Can't find what you need?

Design

Our advanced cable solutions are designed to meet the rigorous standards of the most extreme industries, ensuring seamless performance in demanding environments.

Braiding

Our cable braiding process adds critical protection to our cables using a range of materials to suit the requirements of the environments in which they are be installed.

Taping

Taped cables are designed to provide exceptional thermal stability, chemical resistance, electrical insulation and radiation properties, making them ideal for use in the most demanding applications.

Sintering

Using temperature controlled ovens, Heatsense heat taped material to just below melting point, allowing it to form a cohesive uniform layer that enhances the durability and resistance to harsh environmental conditions.

Extrusion

Using a purpose built extrusion line, Heatsense coat cables with PTFE, known for excellent temperature resistance, chemical inertness, and electrical insulation, is an ideal material for demanding applications.

Twisting & Laying up

The cable twisting process is designed to ensure the cable’s mechanical stability, flexibility, and overall performance, particularly in demanding applications where reliability is paramount.

Sectors we Design Cables for

Aerospace

Heatsense recently achieved the AS 9100 Rev D certified for quality manufacturing in the Aerospace industry. All of our Aerospace cables are manufactured to the highest required specifications.

Nuclear

Our nuclear industry cables are designed to withstand the extreme conditions and stringent requirements of nuclear environments. Heatsense delivers cable solutions you can depend on.

Oil & Gas

With a commitment to quality and compliance with industry certifications, we provide durable and efficient connectivity solutions tailored to the unique challenges of the oil and gas sector.

General Industry

Engineered with durability and safety in mind, our solutions meet the rigorous demands of general industry, enabling efficient and uninterrupted operations across a very broad sector.

Research & Development

Our advanced cable solutions are designed to meet the rigorous standards of research and development, ensuring seamless performance in demanding environments.

You may also be interested in

Heat Resistant Cables

Aerospace Cables

Radiation Resistant

Oil & Gas Cables

General Industry Cables