At Heatsense Cables, we are experts in manufacturing high performance, extreme environment cables, with our cable taping process being a key aspect of our product offerings. Cable taping involves wrapping cables with high-performance materials including PTFE, polyimide and mica to provide extreme protection and enhanced durability. These tapes are known for their exceptional thermal stability, chemical resistance, electrical insulation and radiation properties, making them ideal for use in the most demanding applications.

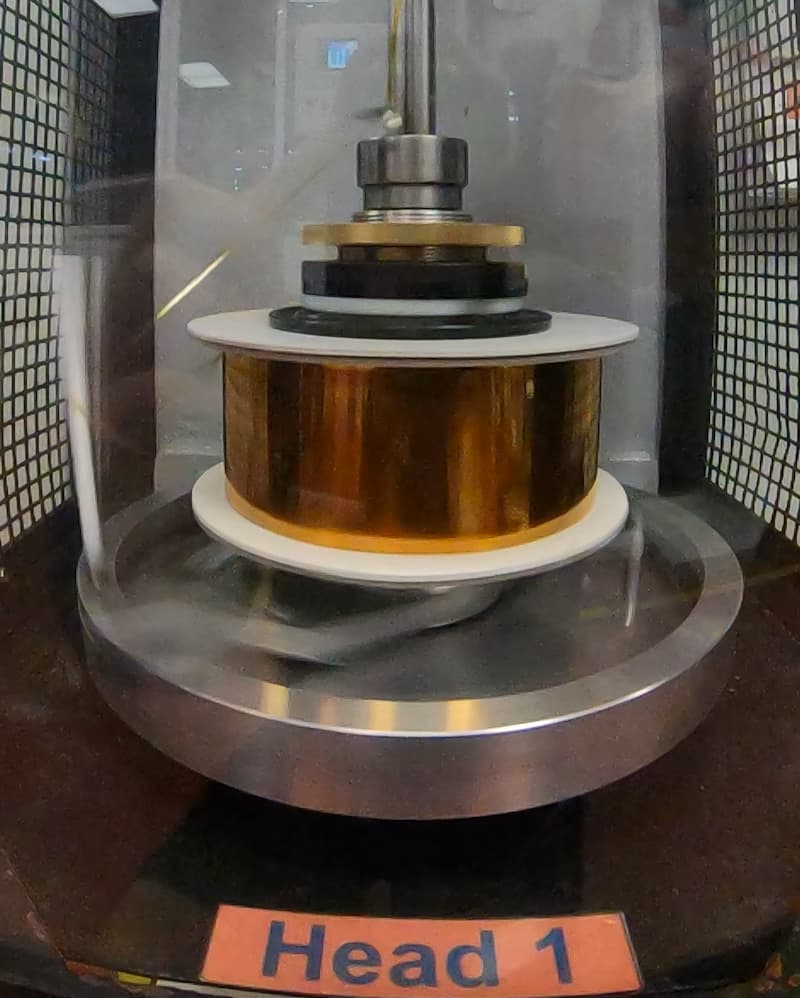

Our taping process utilises state-of-the-art equipment to ensure precision layering and overlapping resulting in consistency and a smooth finish. PTFE tape provides excellent chemical resistance, low friction, and the ability to withstand high temperatures, while polyimide tape offers outstanding thermal stability and dielectric strength and mica ensures fire resistance and fire protection. By combining these advanced materials Heatsense can manufacture cables that can withstand the harshest conditions, from extreme temperatures to exposure to aggressive chemicals and radiation ensuring reliable performance in critical applications.

What benefits do PTFE and Polyimide tapes provide for your cables?

PTFE tape offers excellent chemical resistance, low friction, and high-temperature tolerance, while polyimide tape provides outstanding thermal stability, dielectric strength and radiation tolerance, making them ideal for extreme hazardous environments.

Can you customise the taping process to meet specific requirements?

Yes, we can customise the taping process to meet the unique customer requirements using various high-performance materials and techniques to ensure optimal performance.

What industries benefit most from your taped cables?

Our taped cables are widely used in industries such as aerospace, automotive, nuclear, oil & gas, R&D and medical, where high performance and reliability in extreme environments are essential.

How do you ensure the quality and consistency of your taped cables?

We use state-of-the-art machinery and adhere to stringent quality control measures throughout the taping process to ensure that our cables meet the highest standards of performance and reliability.

What materials do you use in your cable taping process?

We use a variety of high-quality materials, including PTFE, polyimide, mica and various other materials to ensure excellent performance characteristics and protection for our cables.

What is the typical lead time for custom taped cables?

Lead times for custom taped cables vary depending on the complexity of the design and the order quantity. Our team is committed to providing fast turnaround times and will provide an estimated lead time based on your specific needs.

Can't find what you need?

You may also be interested in

Heat Resistant Cables

Aerospace Cables

Radiation Resistant

Oil & Gas Cables

General Industry Cables

Research & Development Cables

Commitment to quality and consistency

Heatsense Cables is committed to innovation and quality, continuously investing in cutting-edge technology and adhering to stringent quality control standards. Our expertise in cable taping with materials like PTFE, polyimide and mica allows us to deliver customised solutions that meet the specific customer needs across various industries, including aerospace, nuclear, automotive, oil & gas, medical and R&D. Our goal is to provide cables that not only meet but exceed industry standards, ensuring exceptional performance and durability in extreme environments.