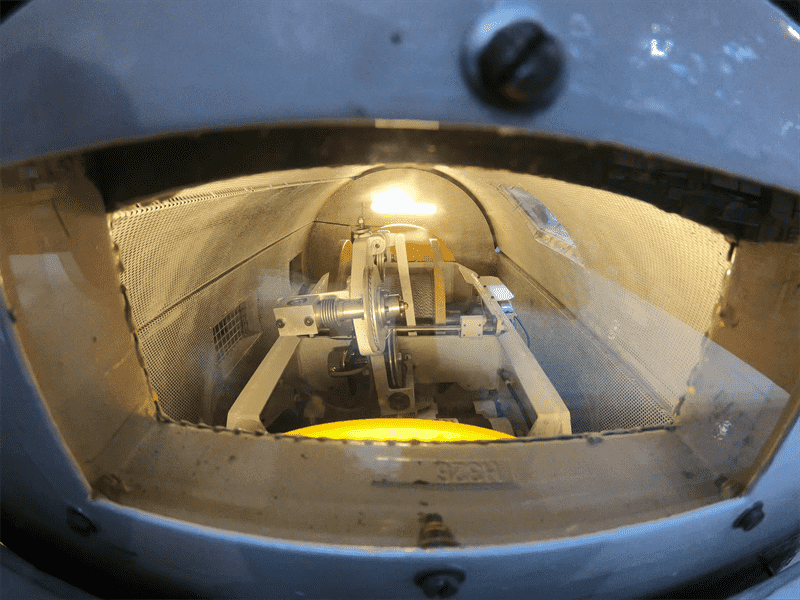

Our cable laying up process utilises advanced machinery and precise control techniques to achieve uniform twisting, tension control to ensure consistent cable geometry. By carefully selecting the lay-length and ensuring optimal tension during the twisting process, we can minimise electrical interference, reduce signal loss, and enhance the overall durability of the cable. This meticulous approach is crucial for applications in aerospace, military, nuclear, automotive, oil & gas, R&D and medical industries, where cables are often subjected to extreme conditions and must perform flawlessly.

Heatsense Cables is dedicated to delivering high-quality, custom-engineered solutions that meet the specific needs of our customers. Our commitment to innovation and excellence in cable laying-up and twisting ensures that our cables provide exceptional performance, even in the most challenging environments. By continuously investing in cutting-edge technology and adhering to stringent quality control measures, we guarantee that our cables meet the highest industry standards and exceed customer expectations.

What is the purpose of cable laying-up or twisting?

How does cable twisting improve cable performance?

Can you customise the cable laying up process to meet specific requirements?

What industries benefit most from your twisted cables?

How do you ensure the quality and consistency of your twisted cables?

What is the typical lead time for custom twisted cables?

Can't find what you need?

You may also be interested in

Heat Resistant Cables

Aerospace Cables

Radiation Resistant

Oil & Gas Cables

General Industry Cables

Research & Development Cables

Why Heatsense for Cable Twisting or Laying up?

Heatsense Cables is dedicated to delivering high-quality, custom-engineered solutions that meet the specific needs of our customers. Our commitment to innovation and excellence in cable laying-up and twisting ensures that our cables provide exceptional performance, even in the most challenging environments. By continuously investing in cutting-edge technology and adhering to stringent quality control measures, we guarantee that our cables meet the highest industry standards and exceed customer expectations.