Heatsense manufactures and stocks a core range of Equipment Wires & Cables. We also offer bespoke solution if you require something very specific.

Equipment Wires & Cables are types of electrical conductors specifically designed for wiring and powering electrical equipment, appliances, and machinery. They are engineered to meet the mechanical, electrical, and environmental requirements of the equipment they serve, providing reliable performance in a wide range of applications.

Click on the datasheet links below to see our full product range or get in touch about a specific requirement you have.

Can't find what you need?

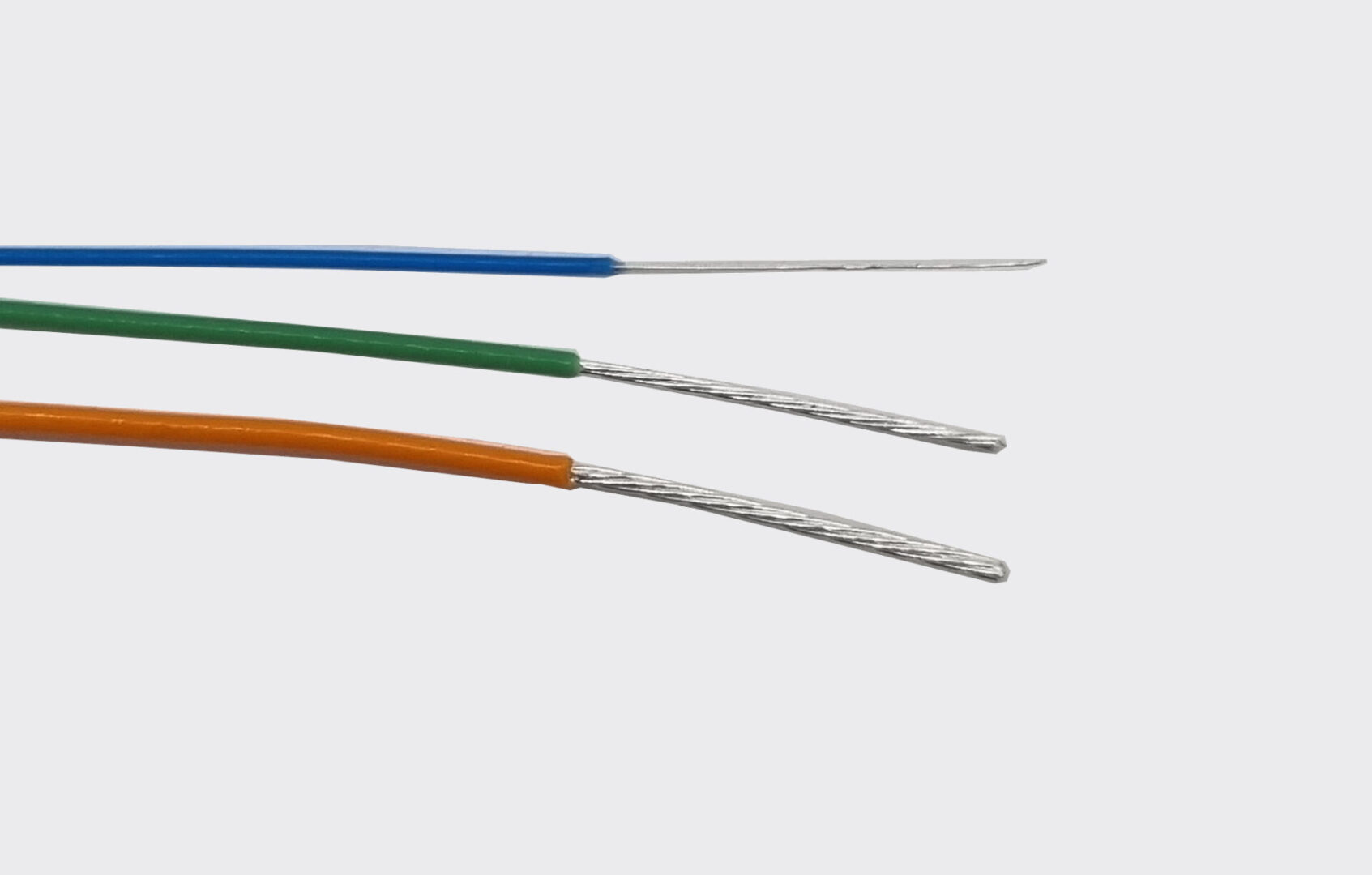

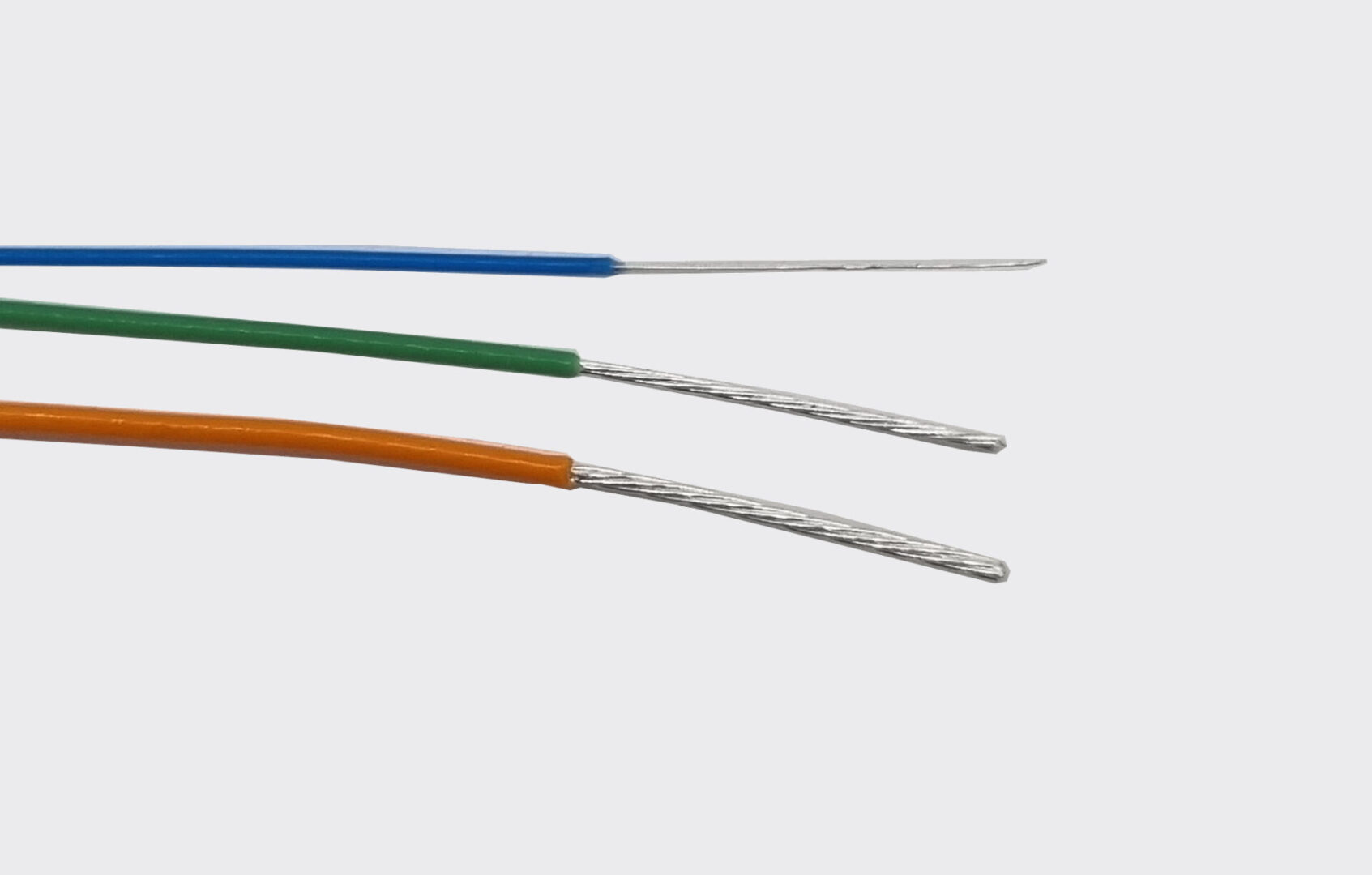

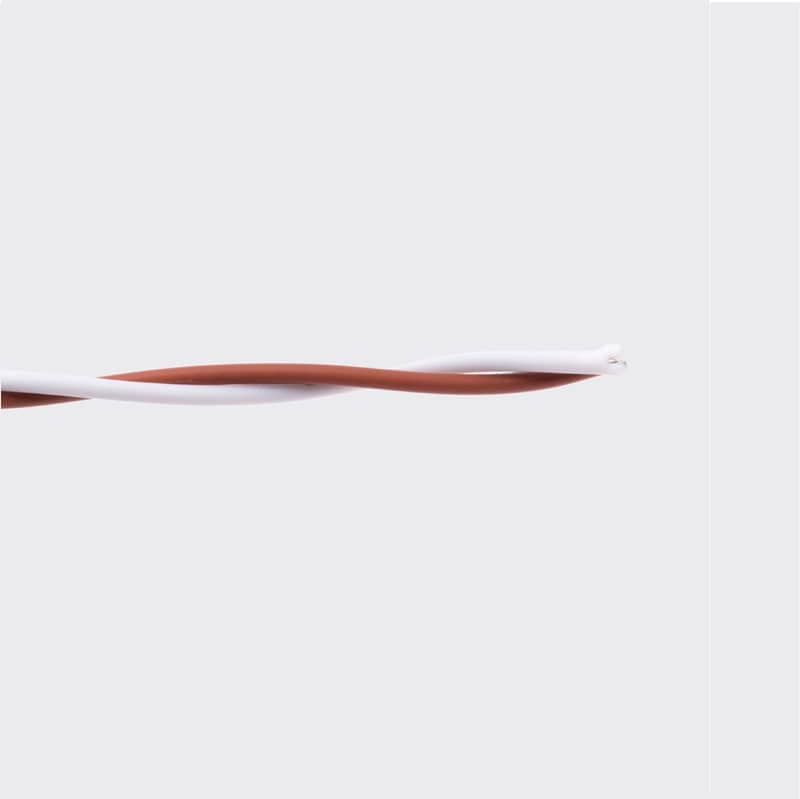

Our Equipment Wire Range

EFGLAS Equipment Wire

PFA Equipment Wire

PTFE Equipment Wire

PEEK Equipment Wire

POLYIMIDE Equipment Wire

ETFE Equipment Wire

FEP Equipment Wire

Product Downloads

You may also be interested in

Heat Resistant Cables

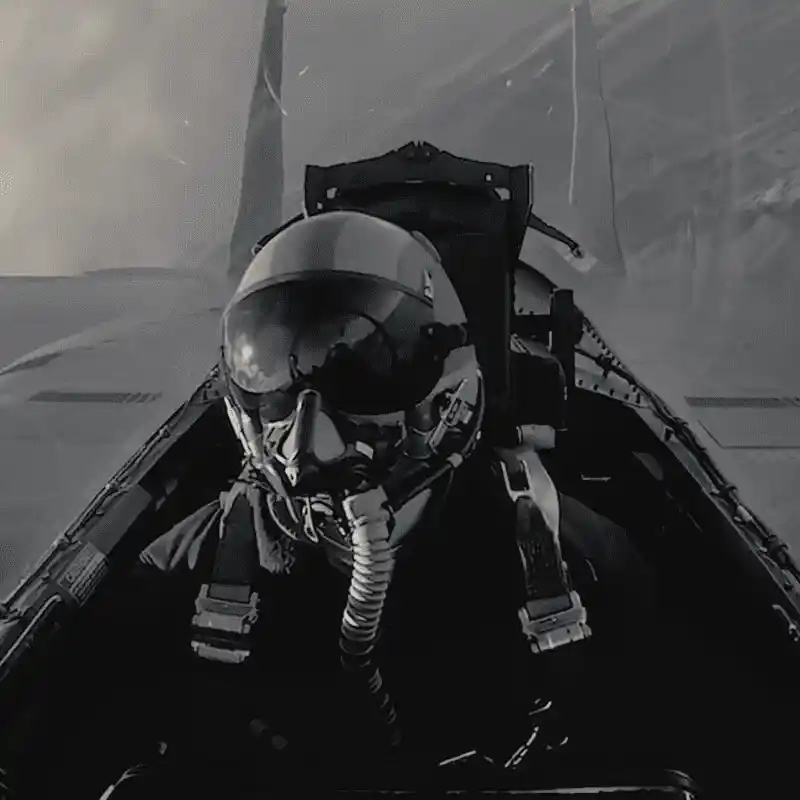

Aerospace Cables

Radiation Resistant

Oil & Gas Cables

General Industry Cables

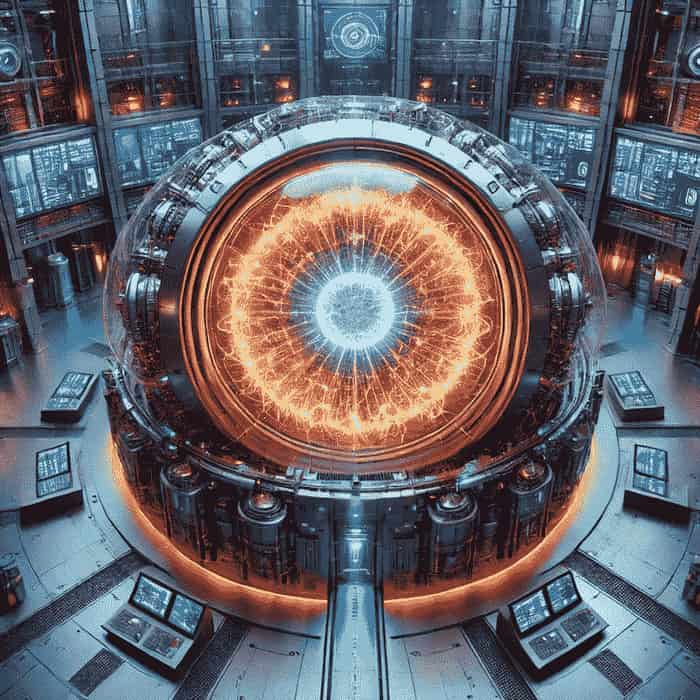

Research & Development Cables

Equipment Wire & Cables FAQs

What cable manufacturing processes are used to protect electrical and signal cables used in extreme heat and radioactive environments?

If you are looking to protect electrical and signal cables used in extreme heat and radioactive environments , you need plenty of layers which have specific protection capabilities. Heatsense apply the following cable manufacturing processes including braiding, extruding, and coating with heat and/or radiation-resistant materials as well as various liquid ingress protection coatings. The specific process used depends on the requirements of the application.

What materials are used for extruding coatings on cables for extreme heat and radioactive environments?

Materials commonly used for extruding coatings on cables for extreme heat and radioactive environments include polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), and fluorinated ethylene propylene (FEP). These materials have excellent temperature and chemical resistance properties.

In the manufacturing process, how are cables tested for resistance to extreme heat and radiation?

Cable manufacturers like Heatsense test for resistance to extreme heat and radiation using a variety of methods, including thermal cycling, radiation exposure (carried out by a specialist partner), and mechanical testing. Testing is typically done in accordance with industry standards to ensure accurate and reliable results.

What is the typical lifespan of cables manufactured for use in extreme heat and radioactive environments?

The lifespan of cables used in extreme heat and radioactive environments depends on a number of factors, including the materials used, the level of exposure to heat and radiation, and the application requirements. Cable manufacturers can provide guidance on the expected lifespan of cables for specific applications.

Can cables be customized to meet specific application requirements for extreme environments?

All Heatsense cables can be manufactured to order, therefore can be customized, combined into multi-strand configurations and braided into a single large cable to meet any specific application requirements for extreme environments. We are constantly innovating with our cables and can work with you to develop a customized solution that meets your unique needs.

How are cables manufactured to protect them against corrosion in extreme environments?

Heatsense cables are manufactured to be protected against corrosion in extreme environments by using materials that are resistant to corrosion, such as stainless steel and a range of plastics. Additionally, a range of different coatings can be applied to further protect the cables from corrosion. Heatsense cables design team will support you in choosing the right materials and coatings for your specific application.