Heatsense manufactures and stocks a core range of Thermocouple Cables. We also offer bespoke solutions if you require something very specific.

Thermocouple Cables are specialized wires used in conjunction with thermocouples to measure temperature. A thermocouple is a temperature sensor that consists of two dissimilar metals joined together at one end, creating a junction where the temperature is measured. The thermocouple cable carries the small voltage generated at this junction to a measurement or control device.

Click on the datasheet links below to see our full range or get in touch about a specific requirement you have.

Product Downloads

Why choose Heatsense for Thermocouple Cables?

Heatsense Cables are a UK-based specialist cable manufacturer who can produce a broad range of Thermocouple Cables for use in the most challenging and extreme environments. With clients from the Oil and Gas to the Steel and Nuclear industries, we are confident we have a cable to suit your requirements. If we haven’t listed exactly what you need in our product list below, please get in touch with our team of expert cable designers who may be able to design and create a bespoke cable to meet your requirements. All of our cables are made to order so you can rest assured we have a solution for you.

Our thermocouple cables have now been certified Fit For Nuclear and we have supplied cables into a new built Nuclear site at very short notice to a completely custom and bespoke design and specification.

Thermocouple Cable FAQs

What are Thermocouple Cables?

Thermocouple cables and extension wires allow the accurate and electronic measurement of temperature and have numerous industrial applications in specialist and extreme environments.

They generally comprise two strands of conductor made of different metals, one being the positive conductor and the other the negative conductor. The two dissimilar metals in the thermocouple cable are electrically joined at the sensing point. When heated the metals produces a thermoelectric charge (Electro Motive Force, or EMF), which changes as the temperature increases or decreases. The EMF (measured in millivolts) that arises is proportional to the temperature difference between the two conductors at the sensing point.

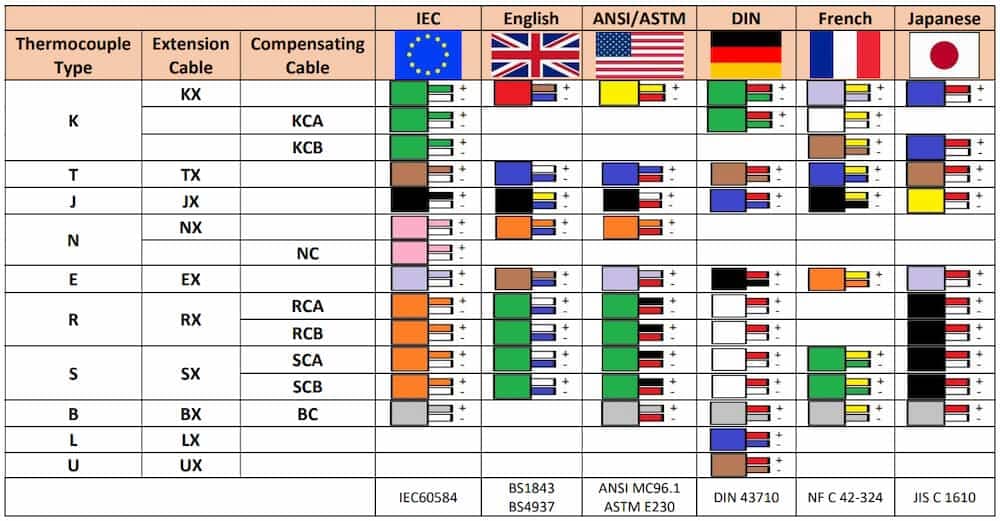

Different temperature applications require different metal conductors, different jacketing/sheathing materials and different calibration. Thermocouple cables are therefore available in a broad range of combinations of conductor, jacketing and calibration. Each pair calibrated to suit a different temperature range and environment. The most common types are manufactured to IEC Specifications J, K, T, N and IEC colour Codes. They are also available in many other local colour codes.

The diameter of conductor used also plays an important part. Generally larger diameter conductors can withstand higher temperatures and are more durable, but have a slower response time than smaller diameter conductors.

Typically, both conductors are insulated then laid or twisted together and finally over-sheathed or over-braided.

Key Characteristics of Thermocouple Cables

- Dissimilar conductors within a single cable

- Insulation types include; PFA, FEP, PTFE or Polyimide

- Choice of conductor combinations according to temperature range and application

- Conductor alloys include; Copper, Constantan, Nickel Chromium, Nickel Aluminium, Iron, Nicrosil, Nisil & Cupronic

- Available as twisted pair, multi-core, flat twin or single shot constructions

- Colour coded insulation for ease of identification

- Excellent resistance to chemicals, oils and lubricants

- Wide temperature performance

- Can be manufactured to meet requirements of BS 60584-2, BS 4937-30, American ANSI MC96.1 & ASTM E230, German DIN, French NFC, Japan JIS, British BS1843 and IEC 60584-1

Typical Applications and Product Data

- Connecting Thermcouple sensors to devices

- Instrumentation & control

- Temperature measurement

- Chemical measurement

How to choose the right Thermocouple Cable for your environment?

When selecting a thermocouple cable, several factors need to be considered. These include the temperature range, the accuracy requirements of the temperature measurement, the chemical and mechanical environment, and any specific industry standards or regulations that need to be met. Consulting with an experienced cable manufacturer specializing in extreme environment cables can help ensure the right thermocouple cable is chosen for your application.

We stock a core range of Thermocouple cables that are all designed and manufactured in our own factory in the UK.

Explore our selected products below. We can also build a bespoke solution if you require something very specific, which is not specified below.

- Temperature range required

- Chemical resistance of the sheath material

- The environment or atmosphere the cable will be exposed to – metals react differently in different environments even at similar temperatures

- Space available and method of installation

What are the different types of thermocouple cables available?

There are several types of thermocouple cables, each designated by a letter combination such as Type K, Type J, Type T and Type N. These types are based on the specific metal combinations used in the cables, with each type having its own temperature range and characteristics. It is important to select the appropriate type of thermocouple cable based on the temperature range and application requirements.

Are thermocouple cables suitable for hazardous environments?

Yes, thermocouple cables are often used in hazardous environments where the presence of flammable gases, chemicals, or high temperatures pose a potential risk. However, it is important to select thermocouple cables that meet the specific safety requirements of your hazardous environment, such as having the appropriate certifications and ratings.

Can thermocouple cables be customized for specific applications?

Yes, thermocouple cables can be customised to meet the specific requirements of your application. Cable manufacturers specializing in extreme environment cables can work closely with you to determine the best thermocouple cable configuration, including the conductor material, insulation type, shielding, and overall construction, to ensure optimal performance and reliability.

TYPE K Thermocouple Cables

TYPE J Thermocouple Cables

TYPE N Thermocouple Cables

TYPE T Thermocouple Cables

You may also be interested in

Heat Resistant Cables

Aerospace Cables

Radiation Resistant

Oil & Gas Cables

General Industry Cables