Heatsense Installs & Commissions New High Melt Extrusion Line

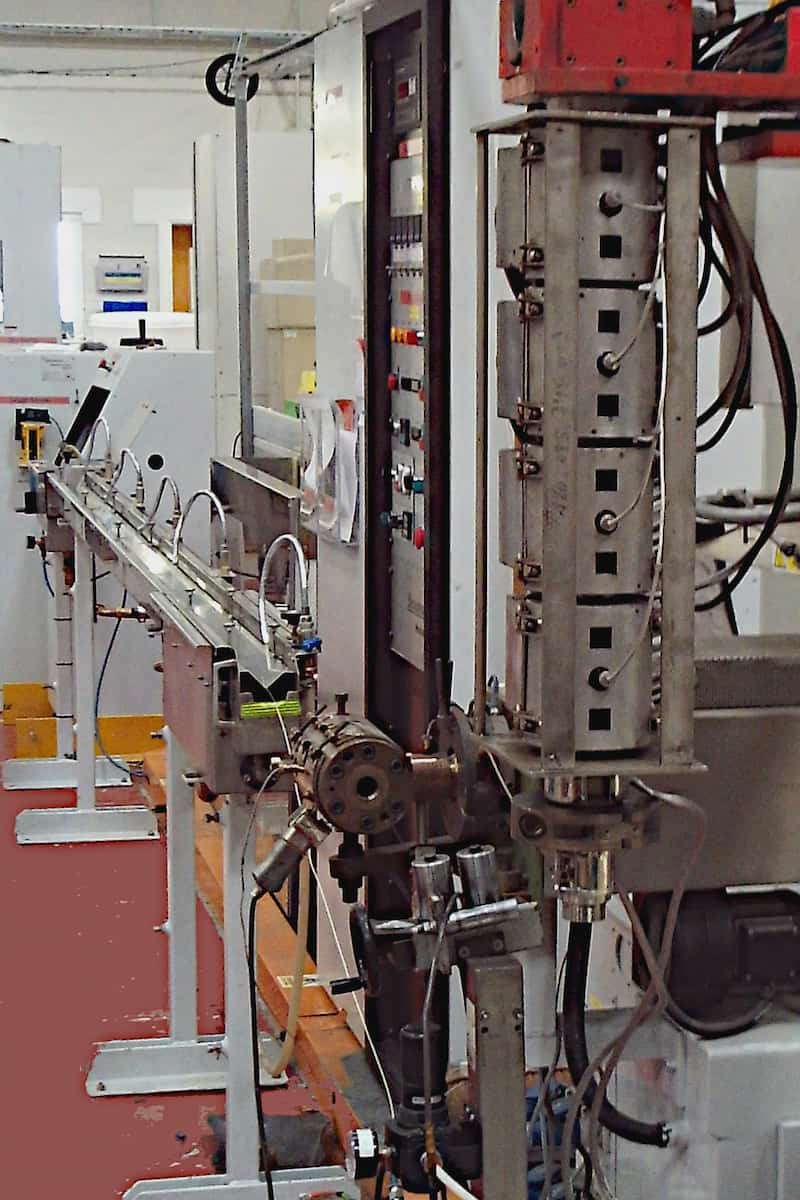

Heatsense installs and commissions new 25mm High Melt Extrusion Line. The new line adds additional capacity to the company’s broad range of extrusion, taping, sintering, laying-up, braiding and ancillary processes.

Heatsense operates 5 high melt lines with extruder barrel sizes ranging from 25mm to 50mm. High melt processable materials include, PTFE, PFA, FEP, ETFE, PEEK.

High melt cable extrusion is a specialized process used to produce high-performance cables for demanding applications. The process involves precise control of high temperatures and specialized equipment to handle the unique properties of high melt polymers. The resulting cables offer exceptional performance in terms of temperature resistance, chemical resistance and mechanical strength, making them invaluable in numerous high-tech industries.

Heatsense Cables, established in 1984, is regarded as the UK’s leading specialist high-performance thermocouple and signal cable manufacturer. Its manufacturing capabilities cover a broad range of specialist cables that operate in extreme environments. The company is a technology leader in fluoropolymer extrusion, high-performance taping and cable wrapping. Related processes include cover sintering, colouring, etching and the application of various specialist coatings. The range covers cables that are resistant to flame, oils and chemicals and which operate in ultra-high vacuum, cryogenic and high radiation environments. Markets include aerospace, nuclear, automotive, medical, R&D, Oil & Gas and general industry.

Heatsense is EN9100:2018, ISO14001:2015 Accredited, F4N (Fit for Nuclear) Approved and Cyber Essentials Certified Plus, JOSCAR Certified and ADS Member.